Dyeing with natural colour pigments is no simple task. In addition to properly processing the pigments in an ecological manner, the preparation of the material to be dyed is often required. It is crucial to choose colors that are as lightfast and wash-resistant as possible, ensuring they neither fade quickly nor lose colour during washing. Two of the few natural plant-based color pigments that meet these criteria for dyeing plant fabrics are Turmeric and Indigo.I have achieved wonderful results using these two color pigments (see e.g. Plastic free).

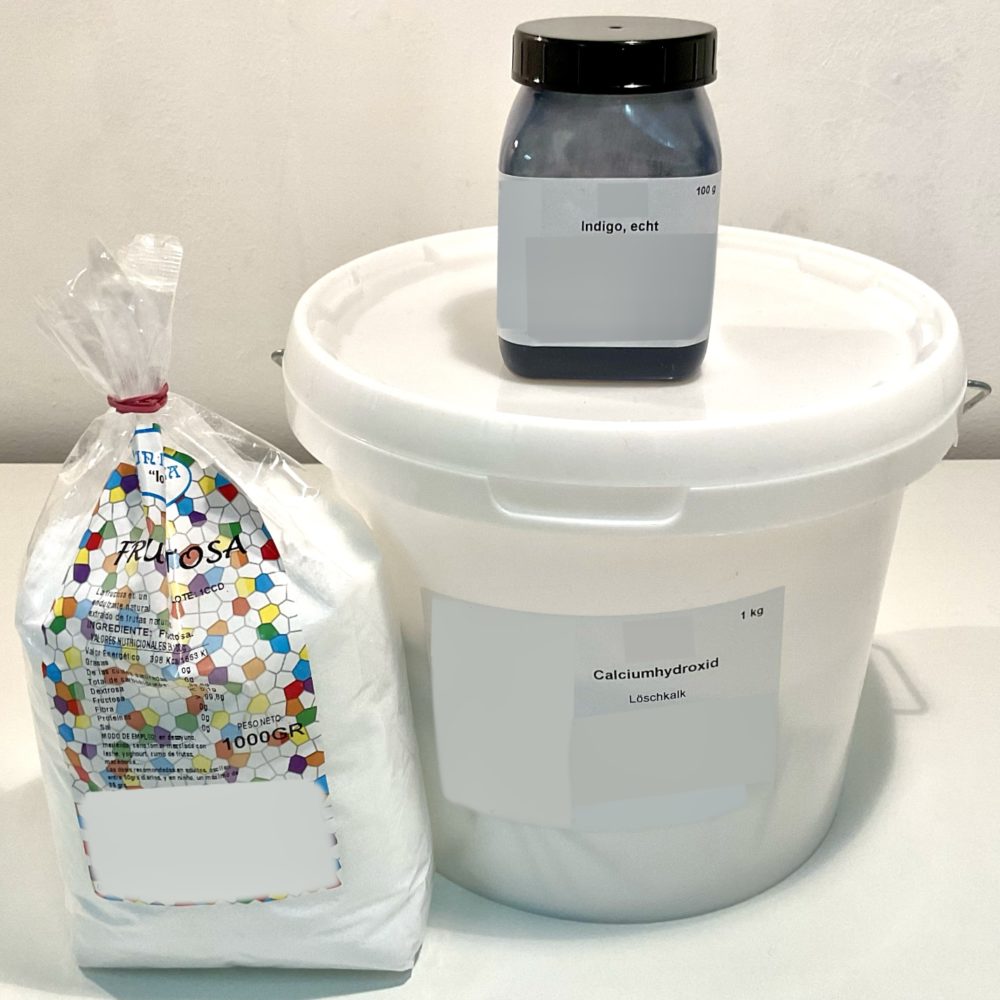

Additionally, dyeing with these plant pigments is environmentally friendly, requiring no more than three main ingredients for plastic-free dyed products (unbleached and undyed cotton, metal, and plant colour pigments):

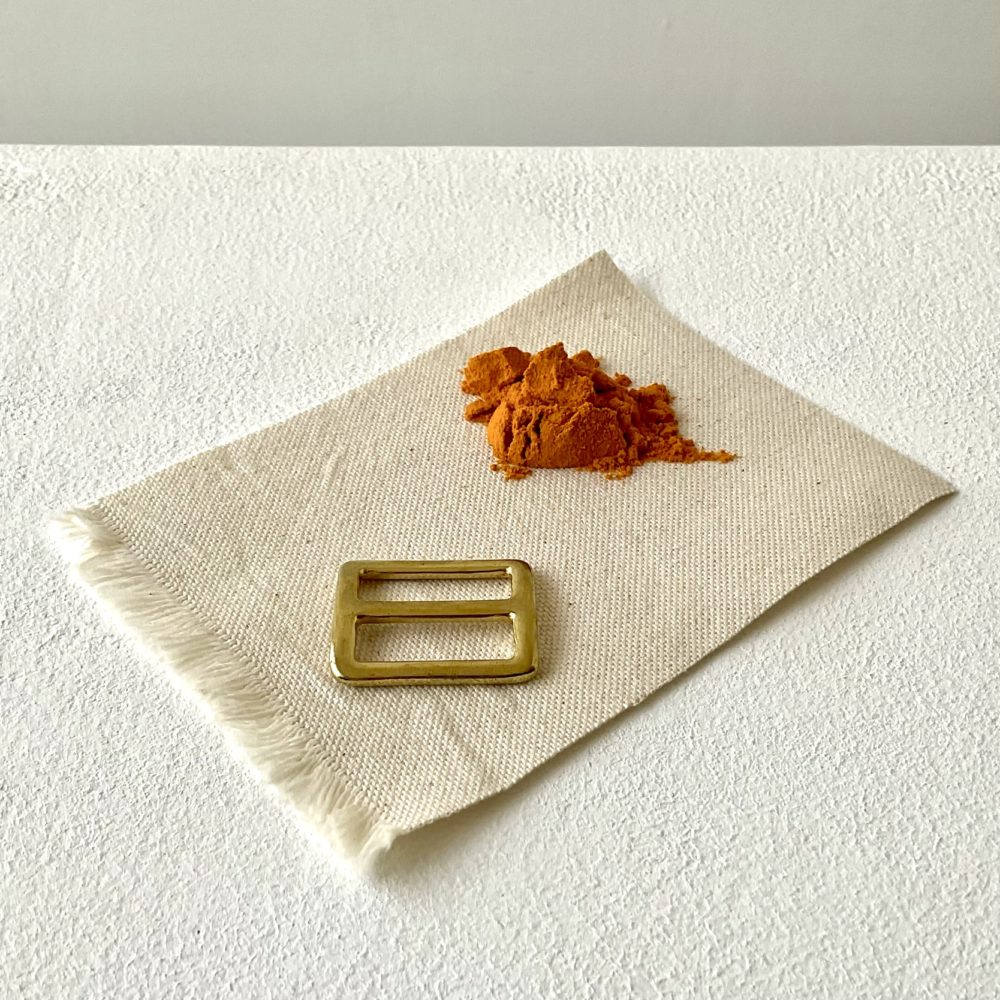

Turmeric Turmeric (or Curcuma, Yellow Ginger, Saffron Root, Yellow Root) is a plant species within the ginger family (Zingiberaceae). Originating from South Asia, it has traditionally been cultivated in tropical regions, but its cultivation has now spread globally (e.g. to Austria). The rhizome closely resembles that of ginger but is intensely yellow. Turmeric can be used fresh or dried as a spice, medicine (for digestion, immune system strengthening, prevention of infections, and respiratory diseases), and dye. Until the 20th century, it was commonly used for dyeing fabrics, paper, varnishes, and ointments. Since then, synthetic pigments are mainly employed to achieve the colour of turmeric.

For dyeing with turmeric, no other ingredients are needed besides a mordant (in which the textile is placed for at least 12 hours before the dyeing process), turmeric, and water. After mordanting, the fabric is washed, then dyed for at least an hour in a warm turmeric bath. Subsequent oxidation in the air aids in fixing the colour. Once dried, the dyed material can be washed in a washing machine and is ready for use.

Indigo. (from the ancient Greek word indikón, "the Indian") is an organic pigment with very high colour strength, lightfastness, and wash resistance; it is also sparingly soluble in water. The color shade named after it is designated as Pigment C.I. Pigment Blue 66 and as Vat Blue 1 in vat dyes. Indigo is one of the oldest and most well-known pigments, having been used for dyeing textiles since prehistoric times. Initially, indigo was exclusively derived from plants (such as the leaves of woad or the indigo plant). In the late 19th century, the industrial and cost-effective development of synthetic indigo began, gradually replacing natural indigo. Apart from "Pencil Blue" and blueprinting, indigo is still most commonly used in vat dyeing.

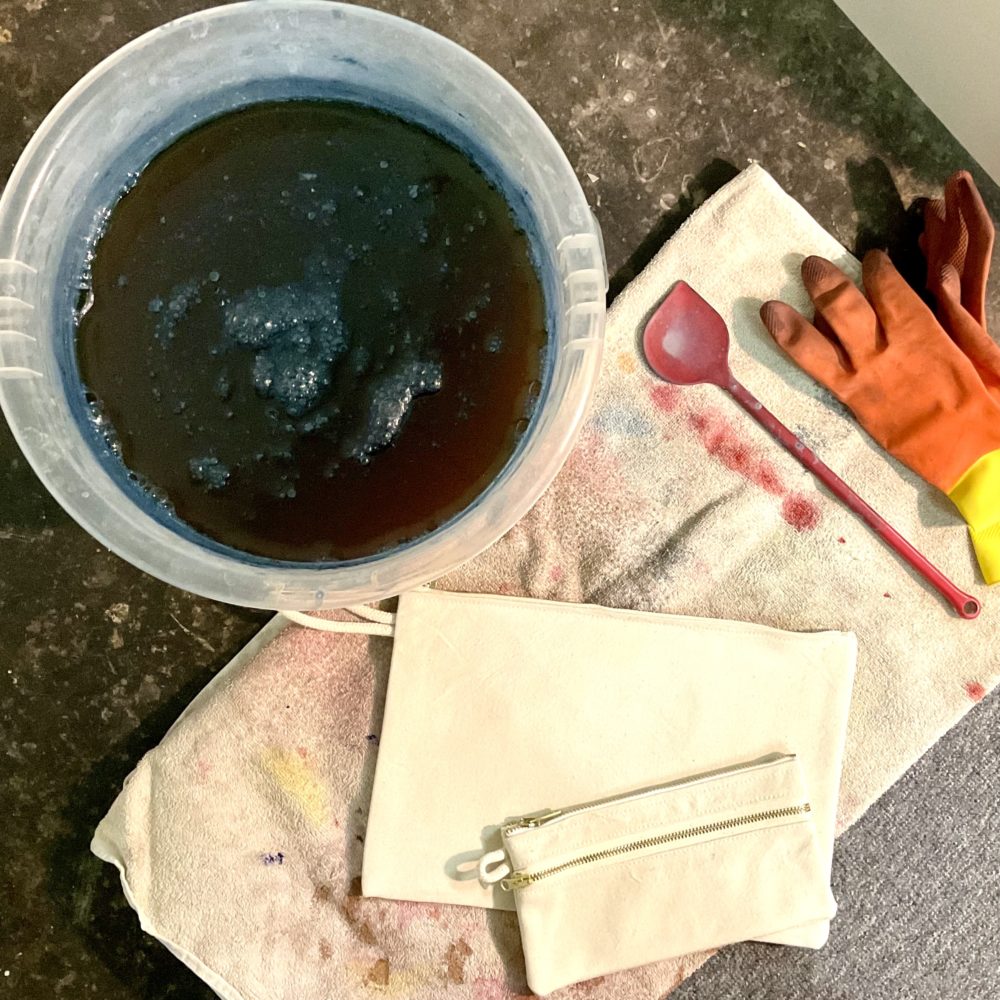

Although the textile does not require pre-treatment, dyeing with indigo requires more preparation than dyeing with turmeric. Initially, the indigo needs to be "reduced" to make it water-soluble. A stock vat is first prepared (with pigment, water, fructose, and, for example, calcium hydroxide). After maturation, the stock vat can be diluted with water. It needs to mature again, indicated by the copper sheen and the blue "indigo flower" on the surface. The textile can be dyed multiple times (immersed in the vat) based on the desired colour intensity. The vat itself fluctuates in colour between reddish-brown and dark green, and the dyed fabric appears greenish in the liquid, turning blue only through oxidation in the air. After air-drying, the dyed material can be rinsed with vinegar (to adjust the pH from around 12 to 6) and washed in a washing machine, making the fabric ready for use.